For most consumer beverages, the even mixture and distribution of ingredients, known as homogeneity, may be nothing more than a measure of visual aesthetics and personal preference. This is not the case for beverages containing cannabinoids such as CBD and THC, where the cannabinoids should be evenly dispersed so that the first sip has the same amount of active ingredient as the last. The best way for a product producer to deliver cannabinoids in a way that ensures this even distribution, stability over time, and accurate label claims is through a water-soluble emulsion…but not all emulsions are created equally.

What Is an Emulsion?

An emulsion is a combination of two or more liquids which won’t mix, like oil and vinegar in a salad dressing. Emulsions provide a pathway to present these two liquids as a uniform mixture. By definition, emulsions are unstable and will eventually break (ie: the oil and vinegar in the dressing eventually separating); however, in a well-formulated emulsion, the separation process can be slowed.

What makes two liquids immiscible? In the case of water and CBD or THC, water is a fat and oil-fearing molecule, whereas CBD or THC is a water-fearing molecule, so by nature, they repel one another. Most oils used for foods and cooking like olive oil and canola oil are considered water-fearing.

Emulsions can be found in products ranging from mayonnaise, Hollandaise sauce, and salad dressings to soft drinks, functional beverages, pharmaceuticals, and even baked goods. In terms of creating infused food and beverages, the introduction of cannabinoids to water-based formulations is a relatively new application. Cannabinoid requirements bring an extra level of complication to the emulsion system, primarily uniformity and stability over long periods of time, coupled with managing their extreme bitterness.

How a Cannabinoid Emulsion Functions in an Infused Product

As many infused product developers know, cannabinoids can be tricky ingredients to work with, since oil-based ingredients are not always easy to add to a product. One aspect of cannabinoid extract that proves challenging is the sensory profile, which can be undesirable to some consumers because of its slightly bitter taste and “weedy” smell. It can also be hard to tell if the oil has been evenly dispersed in the mix, which could result in inaccurate dosing and inaccurate label claims.

Working with an emulsified version of the cannabinoid extract solves both of those problems. In an infused food or beverage, a cannabinoid emulsion acts in the following ways.

- It isolates the negative sensory aspects of the cannabinoid;

- It enhances potential flavor profiles;

- It provides a highly uniform/homogeneous and stable platform for the active cannabinoids;

- It can be diluted and remain stable in a finished product

How and Why Emulsions Fail

Gravity is one of the biggest enemies of emulsions. The force of gravity is a direct cause of both creaming and sedimentation, two ways an emulsion can show that it is unstable.

Creaming

If you’ve ever had the experience of taking a first sip of an infused beverage and it tastes terrible because all of the cannabinoids have migrated to the top of the can or bottle, you’ve experienced creaming. Creaming happens when the oil droplets separate from the emulsion and migrate upwards. Not only does this result in a negative sensory experience, but it also means the dose is not uniformly dispersed throughout the beverage.

Sedimentation

Sedimentation is basically the opposite phenomenon of creaming; the droplets to move downward and settle at the bottom. This might not be apparent right away if you’re drinking an infused beverage in a can, but if you’re consuming a drink in a glass bottle, you’d be sure to notice emulsion particles clumped together at the bottom of the bottle.

Coalescence and Flocculation

Coalescence occurs when the oil droplets recombine and grow in size over time. They typically form a solid oil layer or ring at the top of the liquid, which can’t be re-dispersed. When flocculation occurs, the forces between oil droplets are out of balance, leading to a collection of droplets grouped together. These typically appear at the top, but they can form at the bottom as well. Much like someone drinking a beverage where creaming or sedimentation has occurred, the sensory experience will likely be unpleasant in both scenarios because of the lack of consistency from one sip to the next. The dose will also not be uniformly dispersed in beverages where these are occurring.

Ways to Mitigate Emulsion Failure: Measuring Particle Size and Distribution Over Time

By definition, emulsions are unstable and will eventually break. For simple emulsions like oil and vinegar salad dressings, separation can occur within seconds. However, for well-formulated emulsions, the process of separation can be slowed to months and years.

The size of the particles and their distribution throughout an emulsion are equally important to stability, homogeneity, and safety. As particle size decreases, the surface area of the oil increases, typically leading to an increase in stability.

It is important to remember that it is not just the formula that makes an emulsion successful, but the formulation combined with specific processing to ensure product uniformity and safety.

SōRSE has been intentionally designed to provide exceptionally long-term uniformity, homogeneity, and stability over time. The R & D and Operations teams utilize a number of analytical techniques to demonstrate and verify stability, uniformity, and cannabinoid assay.

The forces of gravity can be overcome by manipulating several variables, including viscosity of the water phase, solute concentration, and increasing the density of the dispersed oils with weighting agents. While thickening the liquid is likely the easiest way to increase stability by directly slowing the flow of particles, it’s not practical because it can negatively impact sensory aspects such as mouth feel.

Product Stability and the Superiority of SōRSE

It is not just the formula that makes an emulsion successful, but the formulation combined with specific processing to ensure uniformity and safety. SōRSE’s water-soluble emulsion has been specifically designed to provide long-term uniformity, homogeneity, and stability over time, which are verified using a number of analytical techniques.

Particle size and distribution throughout the medium are equally important to homogeneity, stability and safety. Particle size also impacts the emulsion’s clarity and turbidity. The relationship between particle sizes is not linear. If size is the only method of stabilizing an emulsion, the size must be small enough for the forces of gravity to be weaker than the intermolecular forces of the particles. As particle size decreases, the surface area of the oil increases, typically leading to an increase in stability.

How SōRSE Measures Homogeneity and Stability

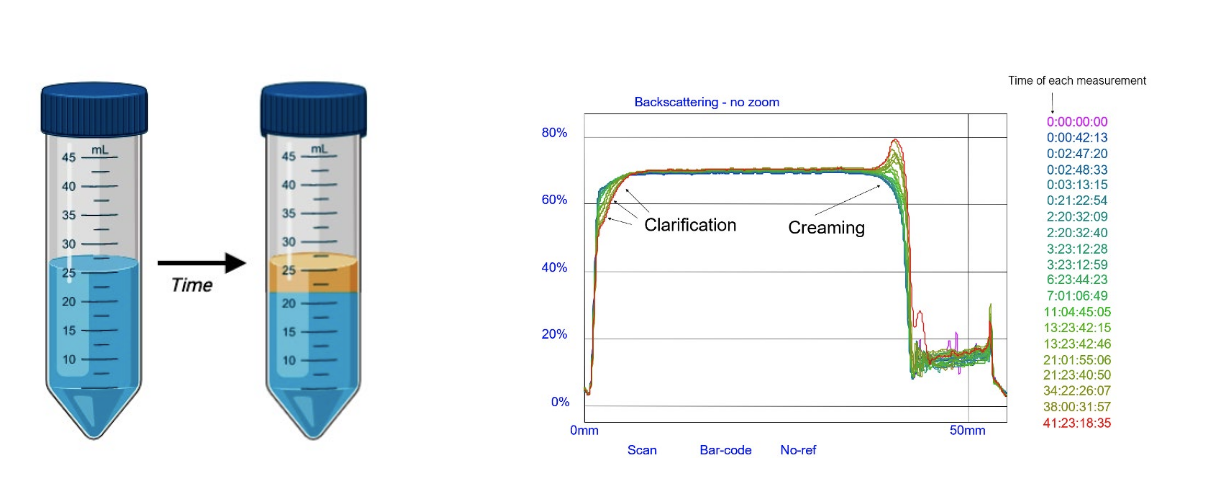

SōRSE utilizes the Turbiscan, which utilizes static multiple light scattering to measure changes in the emulsion system via backscattered light and transmitted light. This technology is able to detect very small changes in a product well before creaming or sedimentation would be visible to the naked eye. It verifies that SōRSE emulsions remain stable for up to one year.

Consistent small particle size with a narrow range is most beneficial for long-term stability. To determine particle size, SōRSE utilizes a high performance laser diffraction analyzer. This equipment determines particle size with sensors that detect wavelength, relative refractive index, and scattering angle, and gives the user a histogram of size variation. The distribution range given by the histogram allows further predictions and indications of stability.

SōRSE also uses High Performance Liquid Chromatography (HPLC) Chromatography to make qualitative observations and quantitative determinations by separating a solution into individual components based on molecular weight and the ability to flow through a medium.

Final Thoughts

Some specific challenges working with cannabinoids include maintaining uniformity and stability; achieving desirable sensory; achieving quick, repeatable onset with predictable experience durations; and ease of use in manufacturing environments. In their raw form, cannabinoids are notoriously sticky and viscus; when converted into an emulsion, they are much easier to integrate into a beverage or food product. With ease of manufacturing in mind, SōRSE’s water-based emulsion easily dilutes in either a tank or individual bottle environment. The two powder forms are designed for either dry mixing or tablet compression or, in the case of the agglomerate, easily reconstituted beverages. The emulsion’s uniformity ensures a predictable onset with near perfect dosing on a consistent basis, which is critical for building trust in the consumer who wants to be sure the product is delivering the amount of cannabinoids promised on the label.

If you are a product developer who has further questions about homogeneity and stability and how SōRSE water-soluble cannabinoids might be the solution you need for your infused product, please reach out to schedule an exploratory call with us today.