With the increased popularity of the cannabis beverage category with consumers and the growing number of infused drinks on the market, there is a lot of talk – and questions — about emulsions and water-soluble cannabinoids. Some of the conversation suggests that emulsions are unnecessary for making an infused beverage and that inexpensive pieces of equipment would allow one to create their own water-soluble solution for beverage production. Here we’ll explore these topics and debunk some of the myths around emulsions.

What is an Emulsion, and Why Is It an Important Ingredient in an Infused Beverage?

Let’s first explain what an emulsion is and why it is needed when making infused products. Emulsions play an increasingly active role in our day-to-day lives, particularly in food and beverages. An emulsion is a combination of two or more immiscible liquids – fluids which will not mix, such as oil and water or the oil and vinegar in a salad dressing. Emulsions provide a pathway to mix or blend immiscible fluids and present them as a uniform mixture. Uniform dispersion in water platforms and foods is one of the largest challenges relating to cannabinoid-infused product development.

Water is a polar, hydrophilic molecule (lipophobic, water loving, fat/oil fearing), whereas cannabidiol (CBD) and tetrahydrocannabinol (THC), along with most lipids, oils, and fats, are non-polar, hydrophobic (fats/oil, lipid loving) molecules. A primary factor of hydrophobicity is polarity.

Some of the reasons an emulsion is beneficial to a cannabinoid beverage system include their ability to: isolate the negative sensory aspects of the cannabinoids; enhance potential flavor profiles; provide a highly uniform/homogenous and stable solution of active cannabinoids; create an emulsion that can be diluted and remains stable.

Whether creating a water-miscible concentrate with an emulsion, suspension, or other solution, a destabilization mechanism will still occur. SōRSE’s technology protects the cannabinoids from destabilizing phenomena such as gravitational forces which lead to creaming and sedimentation. Both creaming and sedimentation are the result of a mismatch of densities between oil phase and the aqueous phase.

If this occurs in a cannabis beverage whether developed with an emulsion or not, the result can be large variations in potency throughout a beverage that could accidentally result in the consumption of most of the container’s active ingredients in the first sips. Other destabilization phenomena can be even more problematic and can result in an irreversible phase separation. These phenomena include Oswald ripening, coalescence, and flocculation.

Myth #1 – You Don’t Need an Emulsion to Make an Infused Beverage, and You Can Make a Water-Soluble Material that Can Be Infused into Beverages with Minimal Cost

There are other ways to make cannabinoids water-soluble, but that doesn’t mean they are the best way to do it, especially if the goal is adding them to a beverage and food item, and the method could have limitations when a company is trying to expand into other legal markets. These methods might bump up against regulatory hurdles from state to state.

While it is possible to purchase the equipment and ingredients needed to make cannabinoids water-soluble, having the ability to test for stability and analyze the solution with an experienced R & D team is critical. Working with a reputable emulsion supplier means more than just purchasing a water-soluble solution – it gives you the knowledge and know-how of an R & D team that is experienced in creating emulsions with a proven shelf life that can be scaled up quickly and easily for beverage production.

Emulsion suppliers also work with testing labs that can ensure a beverage developer is meeting their label claims, and they can help troubleshoot any issues that might arise throughout the process of going to market.

Myth #2 – All Emulsions are the Same

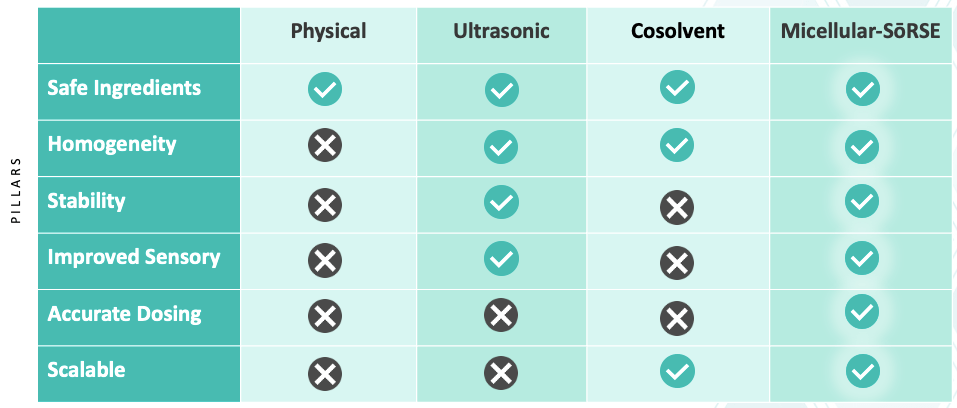

Cannabinoids can be converted into a water-soluble emulsion using 4 different methods, but they are not created equally:

- Physical/Mechanical Dispersions: Mixing or shaking disperses the oil into water

- Ultrasonic Dispersions: Sonic waves break up the oil into small droplets

- Co-solvents: Water-miscible chemicals are used to pull the oil into the water phase

- Micellular Emulsions: Physical ordering isolates the oils from the water phase.

The chart below shows how the four methods compare to one another based on the qualities a beverage producer should be thinking about when evaluating an emulsion.

- Is it made with safe label friendly ingredients?

- Are the cannabinoids evenly dispersed throughout the emulsion (homogeneous)?

- Is the emulsion stable and will it remain stable over time?

- What is the emulsion’s sensory impact?

- Is the emulsion dosed accurately?

- Is it easy to scale production using the emulsion?

Stability in an emulsion is not concluded by a single metric. Homogeneity means that the emulsion disperses evenly and uniformly throughout the product; no separation will occur. A homogeneous emulsion will not have an oil layer at the top or sedimentation at the bottom. SōRSE evaluates the potency throughout a beverage and has been able to demonstrate that a beverage powered by SōRSE that remains undisturbed for up to a year or more will have the same potency (mg/mL) at the top, middle, and bottom.

It is not just cannabinoids that need to remain homogenous and evenly dispersed; colors, flavors, and other ingredients can also fall out of solution or interact with the beverage, causing an unappealing appearance and possible variations in homogeneity.

The micellular method that SōRSE meets all of the requirements needed for creating an infused beverage that will match its label claims and provide a positive experience for the consumer.

Myth 3 – Emulsions are the Primary Factor That Contribute to Scalping

Scalping, the phenomenon of a beverage’s ingredients sticking to the liner in an aluminum can, has been a challenge for beverage formulators for a long time. Many ingredients are absorbed into can liners, not just cannabinoids. Can liners serve several functions such as: protecting the metal from corrosion, absorbing CO2 to prevent the can bursting under pressure, resisting temperature to allow for pasteurization, and preventing unwanted flavor and contamination from metal leaching into the beverage. Knowing that scalping is an issue many infused beverage producers have to contend with, SōRSE, in partnership with a major packaging manufacturer, has conducted studies on scalping and has determined which materials work best with cannabinoids. We have also devised methods for determining the rate of scalping into the can liner in order to properly dose beverages. Through these studies and data analysis, we’ve learned that scalping is not a “one size fits all” scenario, because cannabinoids and flavors scalp at different rates.

Myth 4 — Nano is the sole factor for improving bioavailability

It is common nowadays for manufacturers of cannabis products including beverages to claim what makes a product more bioavailable. Incredibly small particles like those in nano-emulsion are not necessary to create concentrated cannabis solutions that are flavor neutral, lead to fast onset in as little as 10 minutes, and will remain suspended throughout out a product for the duration of the shelf life.

Bioavailability is the degree and rate at which a substance is absorbed into the bloodstream. The bioavailability of cannabinoids varies based on the consumption method and concentration of the cannabinoid of the product they are using. For example, CBD in an edible enters the bloodstream through the digestive tract. SōRSE emulsion is designed to blanket cannabinoids which allows for greater absorption in the intestinal tract. This means that the consumer will feel the effect of the CBD within 8 – 20 minutes.

Nano is descriptor that many cannabis companies use in their marketing, but what exactly does it mean? Materials in the nanoscale range (i.e., with at least one dimension in the size range of approximately 1 nanometer (nm) to 100 nm) can exhibit different chemical or physical properties or biological effects compared to larger-scale counterparts.

Early on, SōRSE recognized the inherent risk in developing a product considered a nano material and the type of safety and toxicology studies that need to be completed. Even if cannabidiol and other cannabinoids were considered GRAS by the FDA (which it has not), additional testing on the nano material would need to be conducted to determine if there are unintended effects.

The bottom line is that nano does not mean higher bioavailability. Just because a molecule is very small doesn’t mean that it will be readily absorbed into the blood stream. Consumers should look for companies that have the data to prove their claims; otherwise, they may not be getting what they expected and paid for.

Myth 5 – Using the term “Nano” is an Effective Way to Market your CBD Product

SōRSE puts consumer safety first, and because of that, we don’t create nano emulsions. Small particle size is part of what makes emulsions easy to scale, but if they are too small, there may be inherent risks. Because the particles are so small, after they are ingested, they are transported throughout the body. This is problematic if they are going to an area where they are not intended to. It is for this reason that nano is not recognized as safe by the FDA.

If the FDA legalizes CBD, nano emulsions may require additional testing to generate safety data and supporting data. Depending on the results of the testing, nano-infused products may require reformulation.

At this time, when considering whether an FDA-regulated product involves the application of nanotechnology, FDA will ask:

- Whether a material or end product is engineered to have at least one external dimension, or an internal or surface structure, in the nanoscale range (approximately 1 nm to 100 nm);

-

- Because materials or end products can also exhibit related properties or phenomena attributable to a dimension(s) outside the nanoscale range of approximately 1 nm to 100 nm that are relevant to evaluations of safety, effectiveness, performance, quality, public health impact, or regulatory status of products, we (FDA) will also ask:

- Whether a material or end product is engineered to exhibit properties or phenomena, including physical or chemical properties or biological effects, that are attributable to its dimension(s), even if these dimensions fall outside the nanoscale range, up to one micrometer (1,000 nm).

-

- These considerations apply not only to new products, but also when changes to manufacturing processes alter the dimensions, properties, or effects of an FDA-regulated product or any of its constituent parts.

Final Thoughts

Emulsions are not new in the food and beverage industry, but not all emulsions and other water-soluble cannabinoid solutions are created equal. It’s important to carefully evaluate the different solutions on the market and ask questions about safety, stability, sensory, and potency. If you are a beverage product developer looking for a trusted supplier and a valuable partner in your journey to market, come to the SōRSE and book a meeting today.

Let’s Chat

Want to evaluate our emulsions? We’d love to learn more about your business and work to create a custom solution.

Tell us a little about yourself and we’ll be in touch shortly.

Privacy Policy. All rights reserved 2021.

Let’s Chat

Want to evaluate our emulsions? We’d love to learn more about your business and work to create a custom solution.

Tell us a little about yourself and we’ll be in touch shortly.

Privacy Policy. All rights reserved 2021.

Let’s Chat

Want to evaluate our emulsions? We’d love to learn more about your business and work to create a custom solution.

Tell us a little about yourself and we’ll be in touch shortly.

Privacy Policy. All rights reserved 2021.

A

better

emulsion

Here is our step-by-step guide on water-soluble emulsion technology’s impact on stability.