Most of those in the cannabis-infused beverage space come to SōRSE because they know we’re the emulsion provider for leading beverages like Cann, St. Ides, Wynk, Rebel Rabbit, and Delta Beverage, to name a few. They also come to us because our roots are in food and beverage innovation with over 200 years’ experience; our products work well both in the short term and have demonstrated superior performance over the test of time. We know beverage.

With the recent growth in the hemp D9 market, there are many new players entering the market and as is often the case, some are making disruptive claims to capture attention.

Some have even raised questions around emulsion technology and whether it’s suitable for cannabis-infused beverages. While we think our clients’ success (low and high dose) speaks for itself, we want to take a step back, return to our roots and explain the benefits of emulsion technology and debunk some myths we’ve heard in the marketplace recently.

Tried & True

Emulsion technology has been in the beverage industry for decades and used in nearly every beverage category – dairy, functional (vitamins/adaptogens), non-dairy alternatives, carbonated, juice, alcohol, protein and supplements, confectionary, etc.

There’s a reason – it works, and it works well.

But it’s more than that. Emulsion technology is designed for food food and low cost beverage manufacturing, simply add the emulsion to the batch, mix for 10 minutes and bottle. It uses natural and clean label ingredients, and when done correctly, creates a shelf-stable beverage that provides even dosing for a consistent and safe experience for the consumer.

Why Emulsions?

First, the term “water soluble” is a bit of a misnomer. Oils are not soluble in water… period. This is where emulsions come in. By first micro-sizing the oil and enrobing it with a water compatible compound, one can develop water

compatibility. A few good examples in everyday life nature are milk or cream, or the cloud/haze in sodas like Mountain Dew, or Fanta.

Yes, there is a lot of science at play with emulsions. So, they are not all created equal. Like so many things, it must be done correctly to maximize benefits and performance.

Emulsion Technology isn’t New, but it has Evolved through Innovation

As mentioned, emulsion technology isn’t new, but cannabinoids have been proven to be particularly tricky to work with, so innovations were made on traditional methods of emulsion technology to create more stable, better tasting, and more consistent infused beverages, particularly when working with THC, an intoxicating cannabinoid. For SoRSE, the innovation and our IP exists both in the ingredients used and the manufacturing process.

SoRSE solutions offer:

- Superior Sensory Profile

- Seamless Integration (available in liquid in powder forms)

- 12-Month Stability (far more than any beverage should need!)

- Accurate Dosing / Homogeneity

- Clean Label

- Consistent Consumer Experience (Consistent & quick onset time of 10 – 15min, and offset ~1 hour* after consumption)

*Onset and offset times provided are an average based on a pharmacokinetic study performed on SoRSE Technology’s solutions by 3rd party pharmaceutical company. Onset and offset times may vary by consumer.

Myth: All emulsions are the same

As mentioned earlier, not all emulsion technologies are created equal, as there are different types for different applications, but there are many factors to consider when evaluating solutions for beverages – homogeneity (even-dosing), flavor, ease of use (for manufacturing), stability (shelf-life), etc. All are equally important because a miss in any one of those areas could lead to an undesirable or inconsistent consumer experience. Brands have one shot with a consumer and it’s not worth risking on technology that doesn’t have a proven track record of success in the food and beverage space.

Emulsion technology broken down to the simplest explanation is the process of reducing the particle size of the oil-based ingredient and enrobing the particles in a water-based solution so when ingested the body treats the particles like water, allowing for faster absorption in the intestinal tract which results in the fast 10 -15 minute onset (where oil-based ingredients are processed, which results in delayed and inconsistent onset and offset times).

But the fast onset isn’t the only benefit. Emulsion technology is also responsible for even-dosing and the consistent onset and offset (~1 hour) for a repeatable (in both duration and intensity) experience. The first sip has to have the same dose as the last in order to create that consistent (and safe) experience.

And last but not least; flavor. Flavor is king – If it doesn’t taste good, the consumer won’t come back for more. SoRSE has become synonymous with clean sensory, often times without the use of sugar, additional flavoring, or bitter blockers for masking cannabis notes.

Delivering consistency at scale is something that should be thought about at every stage of producing a product. In order to ensure scalability, seamless integration and ease of use for manufacturers and co-packers is a must. Reducing the room for error while manufacturing efficiently is the key to scaling and having no limitations on partners for manufacturing.

At SoRSE, we do the hard part, so manufacturing the beverage is fast and easy. SoRSE solutions disperse evenly without agitation (with agitation, they will disperse faster) and can be added into the batch just like any other ingredient making it easy on the manufacturer.

Solutions requiring additional instructions such as “heat before adding” or “do not agitate” should be avoided since it complicates the manufacturing process, as well as repeatability. Standard manufacturing processes mix and pump out the finished formulation in packaging, so it’s difficult to mitigate or control the amount of agitation of a beverage. Instructions that include “do not agitate” typically indicate fragile technology that may result in inconsistent product and consequently failed potency testing with the finished product.

If the technology used to improve onset time or homogeneity / even-dosing for THC breaks during manufacturing or sitting on a shelf over time, it will result in inconsistent and delayed onset times ultimately impacting the performance predictability of a beverage and pose a risk to the consumer.

Myth: Nano means better.

Just like how “new” doesn’t always mean better, neither does “nano”. Yes, nano has become a buzzword in the cannabis industry, but nano is not preferred when it comes to the Food & Drug Administration (FDA), the agency that regulates food and beverage.

Check out the products in the pharmacy – spoiler alert – there aren’t products advertising “nano” and that’s because nano is referring to the very small particle size of the active ingredient and if the particle size is actually nano, it might be small enough to get to places in the body that it isn’t intended to. In which case, products or technology marketing themselves as “nano” may be attracting the wrong kind of attention from the FDA. The FDA is the gate keeper for new ingredients being added to the food and beverage space.

Toxicity and safety testing (typically takes 2 to 3 years with significant cost) are a prerequisite for FDA approval. This is why you do not see “nano” on any food or beverage labels, nano as a physical form has not been proven to be safe in foods and beverages.

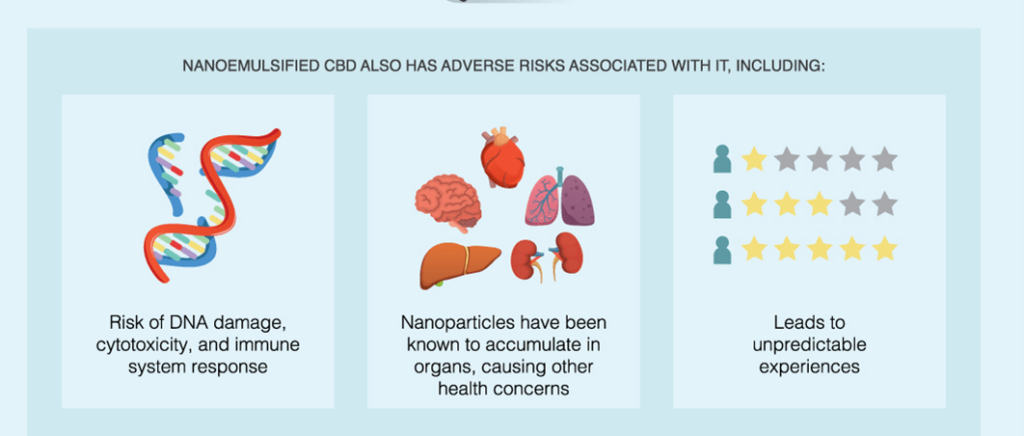

Trait Bioscience, a leading research and development firm dedicated to the study and analysis of water-soluble cannabinoids in CPG products, has also provided potential risks associated with “nano”.

Here’s a couple other facts to know about “nano”:

- Not guaranteed to result in a faster onset than a micro-emulsion (10-15 minutes)

- Not guaranteed to be clear in formulation

- Not guaranteed to be approved by the FDA

- Not necessarily stable, oils will coalesce and seperate over time

Myth: One-Stop Shop is Always Best

Don’t get us wrong, we want to get all our groceries, including low dose beverages, with one trip to a single store if we can, but there are instances where bundling may not be the best decision. One provider controlling input material, manufacturing, and distribution can be problematic and may also come with a hefty price tag.

What happens when you want to make a switch to any component of that equation? If the technology fails, stuck. If a bigger distributor enters the space, stuck. As experienced by those who have been in the infused beverage space circa 2018, multi-year terms and partners providing every service failed to meet expectations and often caused hardship for brands. This is because it’s difficult to all the services needed to manufacture a beverage.

This industry is still in its infancy and many manufacturing and distribution partners from traditional CPG and alcohol will enter into this space. Partner with experts in their respective roles and experienced partners will be able to provide a network of experienced partners that work seamlessly together, from suppliers to distributors.

Conclusion:

Not only is emulsion technology right for beverage; it was designed for beverage. Emulsion technology provides food and beverage compliance, consistent experience, clean labels, and superior sensory. It delivers everything the consumer is looking for, while also being a seamless solution for the producer allowing for scalability. There will always be new innovations, but it’s important that decisions are made with an understanding of regulatory & compliance, consumer safety and scalability.

While we’re building a new category with cannabis beverages, we don’t need to start from scratch and emulsion technology is a large part of the beverage industry’s foundation. Emulsion technology is beverage.

Let’s Chat

Want to evaluate our emulsions? We’d love to learn more about your business and work to create a custom solution.

Tell us a little about yourself and we’ll be in touch shortly.

Privacy Policy. All rights reserved 2021.

Let’s Chat

Want to evaluate our emulsions? We’d love to learn more about your business and work to create a custom solution.

Tell us a little about yourself and we’ll be in touch shortly.

Privacy Policy. All rights reserved 2021.

Let’s Chat

Want to evaluate our emulsions? We’d love to learn more about your business and work to create a custom solution.

Tell us a little about yourself and we’ll be in touch shortly.

Privacy Policy. All rights reserved 2021.

A

better

emulsion

Here is our step-by-step guide on water-soluble emulsion technology’s impact on stability.